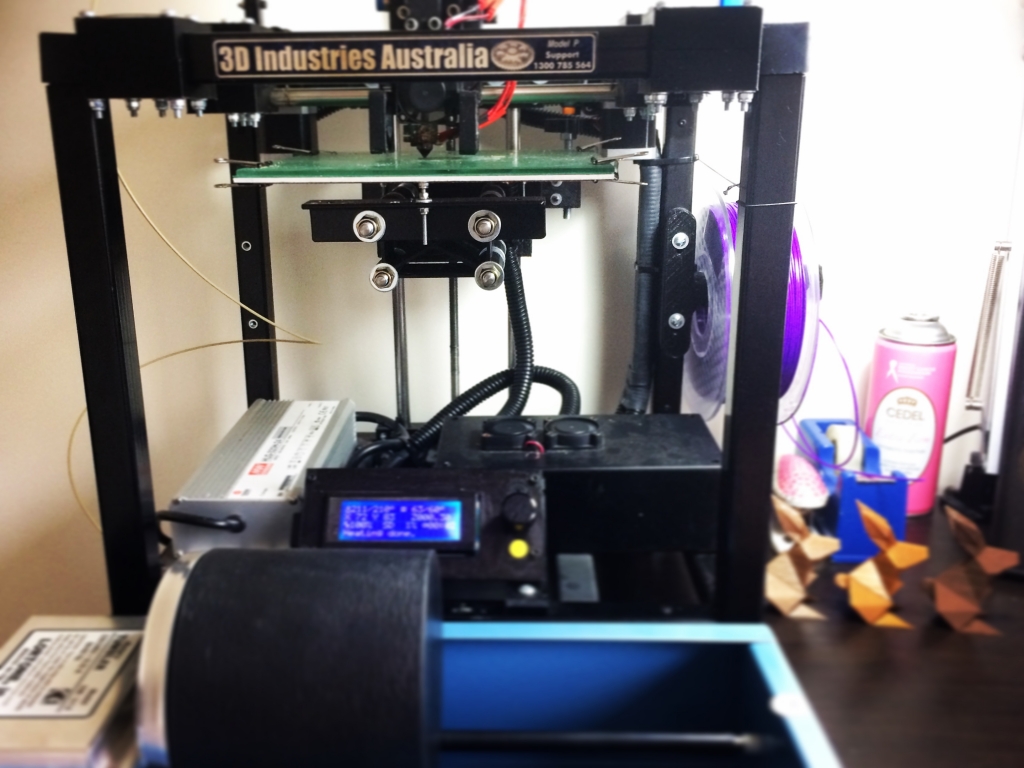

Here’s a sample of the things I’ve been 3D printing in January, with a focus on new filaments, functionality, and sustainability.

I received a few filament samples from Global Filament Sample Depot for Christmas, one of my favourite online stores. The aromatic coffee and pine printed in great quality but didn’t live up to their novelty. The pine didn’t really have any obvious scent, and the coffee smelt more like burnt sugar while printing. I’m really impressed with the metallic sparkle of the frosted bronze PLA, and the coconut also printed quite well.

The bronzefill and brassfill printed out looking a bit like clay and needed a final step to reach the designed ‘casted metal’ appearance. Lucky for me, one of my neighbours owns a gem tumbler. I borrowed it and tumbled the prints with an assortment of brass plated screws for a day, and was very impressed with the finish. The ears had to be glued on again after tumbling, however! The model I used for these tests is the Origamix Rabbit.

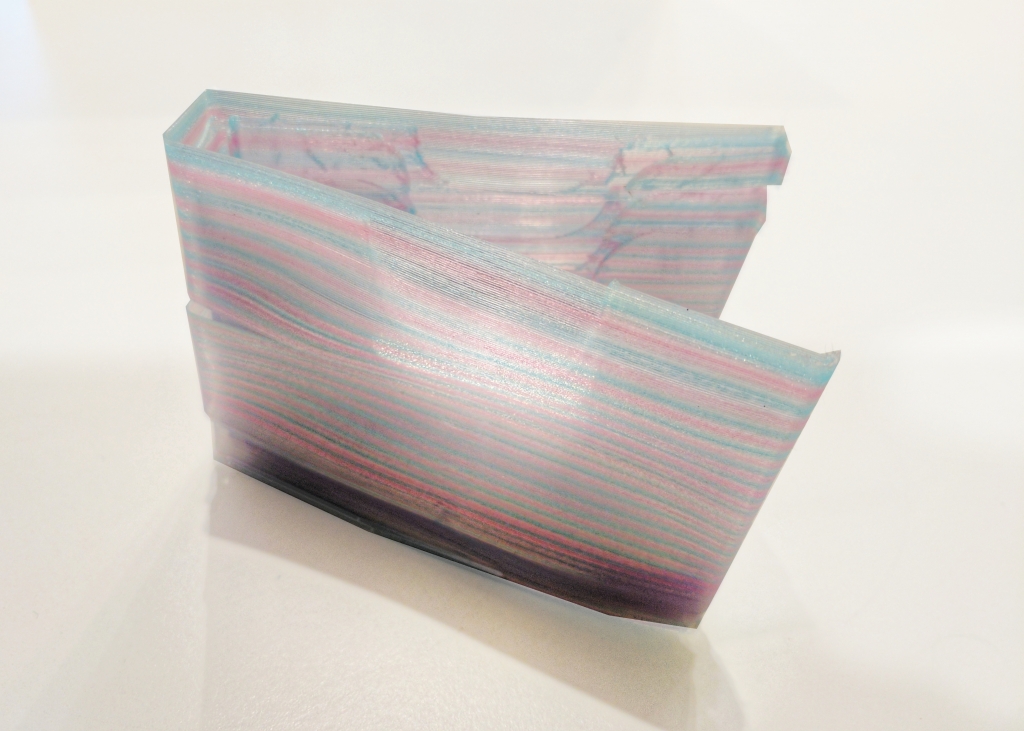

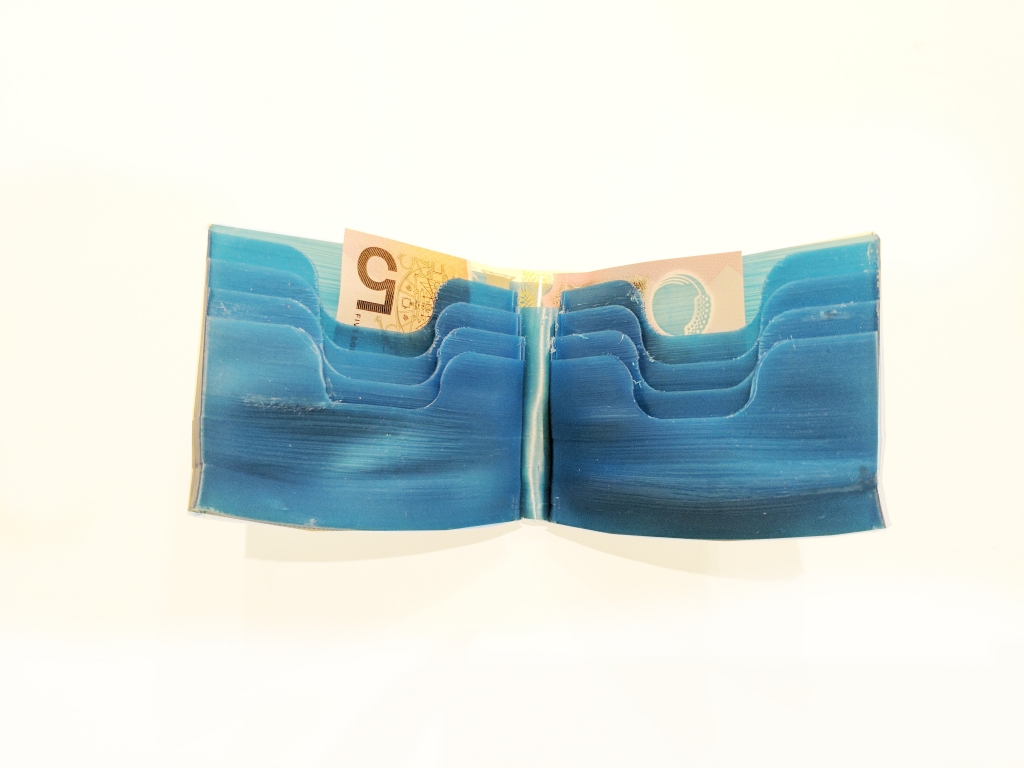

I recently upgraded phones and got rid of my old phone case wallet. I’ve been prototyping a replacement wallet this month to see how functional prints last with ongoing use. I first tried the print with my favourite tie-dyed nylon, but the layer thickness (300 microns) required to show off the beautiful layering also lends itself well to delamination and came apart quite quickly. The blue flexi at 100 microns does the trick. As the wallet folds are one layer thick, the wallet had some slight sagging at the base, but it’s not that noticeable. I’ve been using this wallet for about a week now, and it’s going strong so far!

I recently upgraded phones and got rid of my old phone case wallet. I’ve been prototyping a replacement wallet this month to see how functional prints last with ongoing use. I first tried the print with my favourite tie-dyed nylon, but the layer thickness (300 microns) required to show off the beautiful layering also lends itself well to delamination and came apart quite quickly. The blue flexi at 100 microns does the trick. As the wallet folds are one layer thick, the wallet had some slight sagging at the base, but it’s not that noticeable. I’ve been using this wallet for about a week now, and it’s going strong so far!

Working with 3D printing, especially while prototyping, can often result in plastic that is unused and is often thrown out. I’ve been setting aside my plastic waste for a little while now with the intent of recycling into something new and found an excuse to give it a go. I’m preparing to speak and host workshops with a focus on the sustainability and environmental effects of 3D printing this year and will be preparing samples leading up to the event.

These notepad covers were made by shredding the waste plastic and baking on a tray. The frosted bronze pooled out really nicely, and the white ABS seemed to sag, maintaining some of the original shapes. I followed this video, and next time, I’ll be sticking to PLA as the ABS smelled much worse than expected. Best to keep ABS waste for the filastruder.

If you think of anything cool you’d like me to try, shoot me an email at [email protected]. Big thanks to Athina for photography help, you can check out her instagram at @theenieee.